In this work, we present a novel approach to investigating the dilation of battery electrode materials under varying pressures applied onto the cell stack. For that, the PAT-Cell Force was used, along with specially designed spring yokes that have precisely defined spring characteristics. The PAT-Cell Force is equipped with a force sensor that allows an online measurement of the force applied to the cell stack during cycling. The amplitude of the observed variation in force was then translated into the dilation using Hooke’s Law. Experiments were conducted on cell stacks using NCM-111 and graphite, as well as pre-lithiated LTO and Graphite, to isolate the swelling of the graphite electrode. The results were compared with direct dilation measurements obtained from experiments with the Electrochemical Dilatometer ECD-4-nano.

Approach

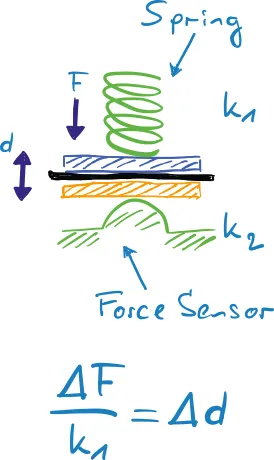

A force F is applied onto the cell stack by loading a precisely defined spring with the spring characteristic k1. The force is measured during cycling with the force sensor placed below the cell stack. Due to the dilation d of the cell stack a periodic variation of the measured force is observed.

A force F is applied onto the cell stack by loading a precisely defined spring with the spring characteristic k1. The force is measured during cycling with the force sensor placed below the cell stack. Due to the dilation d of the cell stack a periodic variation of the measured force is observed.

Assuming that k1 is the softest spring in the system and thus the dominant spring constant of the system, the dilation of the cell stack d can be derived by using Hooke’s Law (left).

Utilising the PAT-Cell Force and specifically designed springs, cells were cycled, and the dilation was calculated using the method described above. The cells consisted of graphite and pre-lithiated LTO. The latter is known to be a zero-dilation electrode, allowing the determination of the dilation of the graphite alone. For comparison, the dilation of the materials was determined in the ECD-4 Nano, where swelling is measured directly using a capacitive distance sensor.

Results

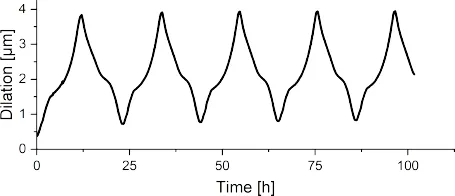

Chart 1 shows the dilation curve of graphite, obtained by direct measurement with the ECD-4-nano. It is of a magnitude of about 3.2 µm. This is taken as a reference point for the dilations derived by the method described above.

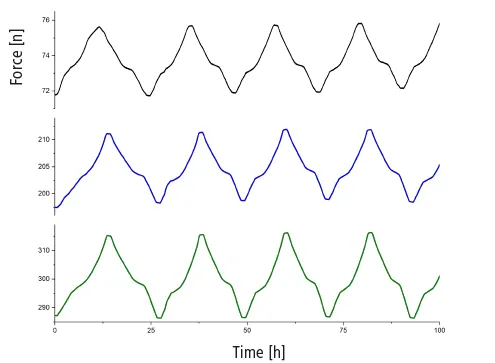

In the second chart, three force measurements are shown, each with a different spring and applied force.

The parameters and the obtained results are listed in the table below:

The force measurements show a clear correlation between the stiffness of the spring (k1) and the amplitude of the periodic variation in force during cycling. Also, the force signal shows a line shape that is very similar to the dilation curve depicted in chart 2. Furthermore, application of Hooke’s Law leads to dilation values that are in good accordance with each other as well as with the dilation obtained directly in the experiment with the ECD-4-nano. Also, a trend can be observed: the higher the applied force, the smaller the derived dilation. Whether this is a correlation or an experimental artifact is the subject of further research.

Conclusion

We show here that the dilation (change in thickness) of battery electrodes can be determined indirectly by measuring the force exerted on the cell stack during the electrochemical cycle. This method works for the entire cell and also for individual electrodes. The results agree well with the results obtained with an EC dilatometer. An advantage of the indirect method is that the initial force exerted on the cell stack can be varied easily and over a wide range. Further research on different materials and higher forces will be conducted in the future.

_

by Dr. Bernhard Bugenhagen et al.

Related products:

ECD-4-nano electrochemical dilatometer

ECD-4-nano electrochemical dilatometer

Advanced Electrochemical Dilatometer for the measurement of electrode expansion with nanometer resolution.

- Capacitive displacement sensor (range 250 μm, resolution better than 5 nm)

- Additional gas pressure (0 to 3 bar) and temperature sensor (-20 to 80° C)

- Cableless connection via PAT socket, with electronic cell tag (PAT-Button)

Operando test cell for investigating battery materials under defined force, temperature, and gas pressure

- Force adjustment and measurement, up to 1500 Newtons

- Built-in temperature, force, and gas pressure sensors

- Cableless connection via PAT socket, with electronic cell tag (PAT-Button)

Comments are closed.