PAT-Cell-Gas-HT

Battery test cell for heating the cell stack to 400°C and analyzing the produced reaction gases

The PAT-Cell-Gas-HT

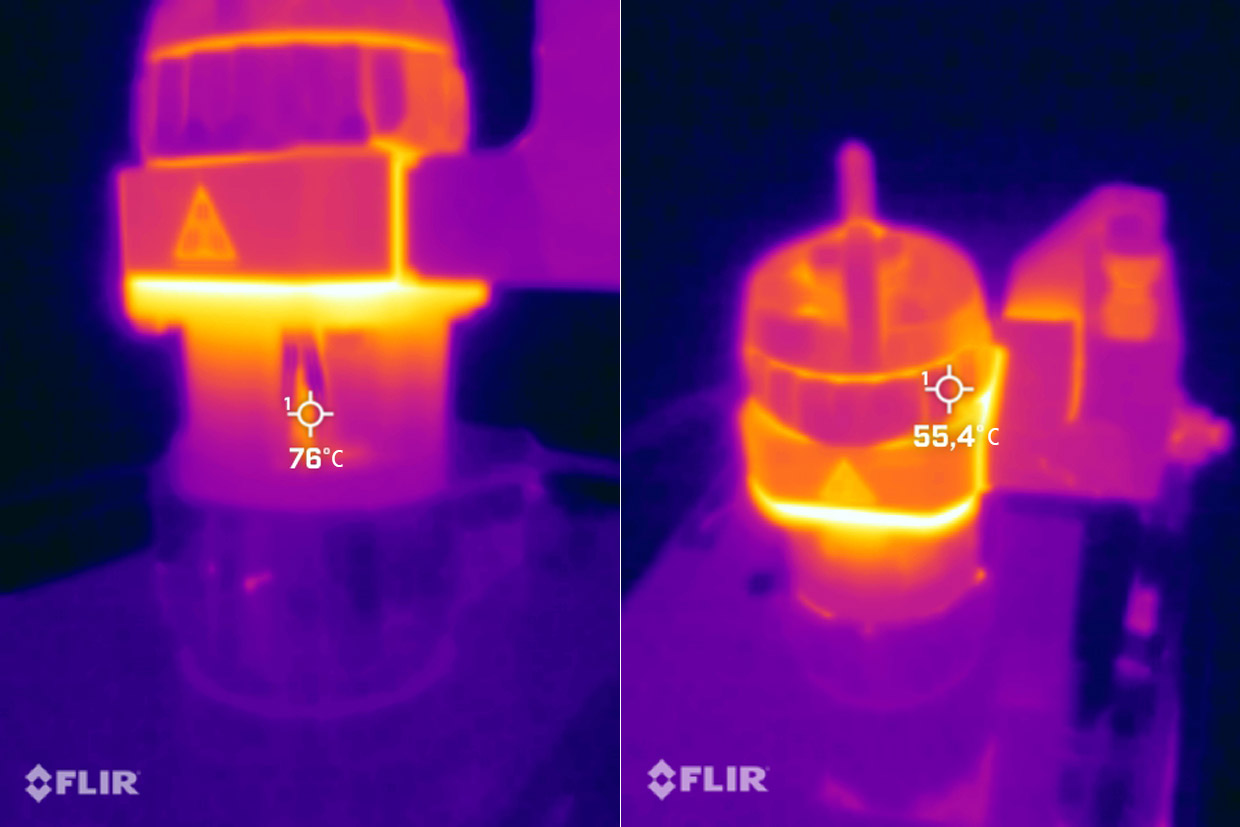

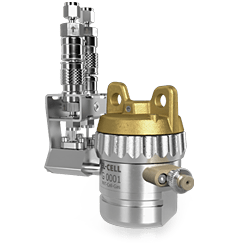

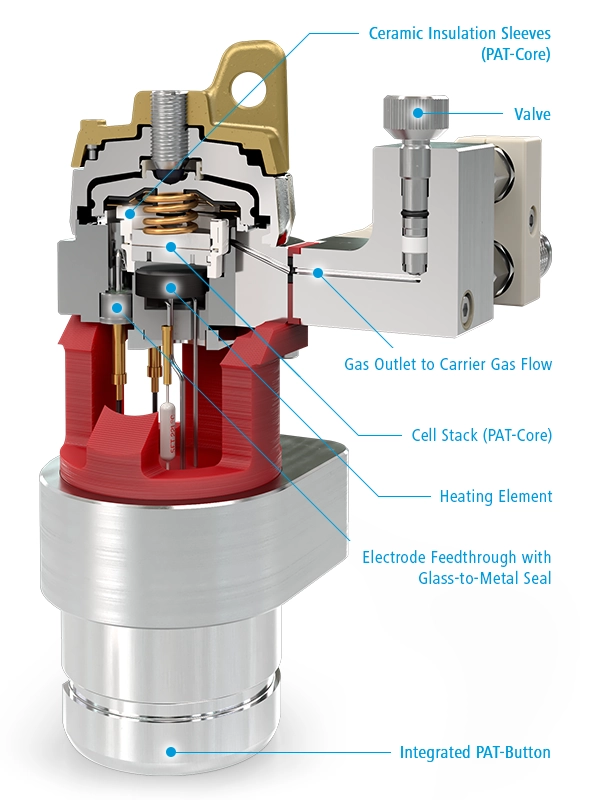

The PAT-Cell-Gas-HT is an in-situ battery test cell designed to simulate thermal runaway by heating the cell stack to temperatures up to 400° Celsius while simultaneously analyzing the reaction gases produced.

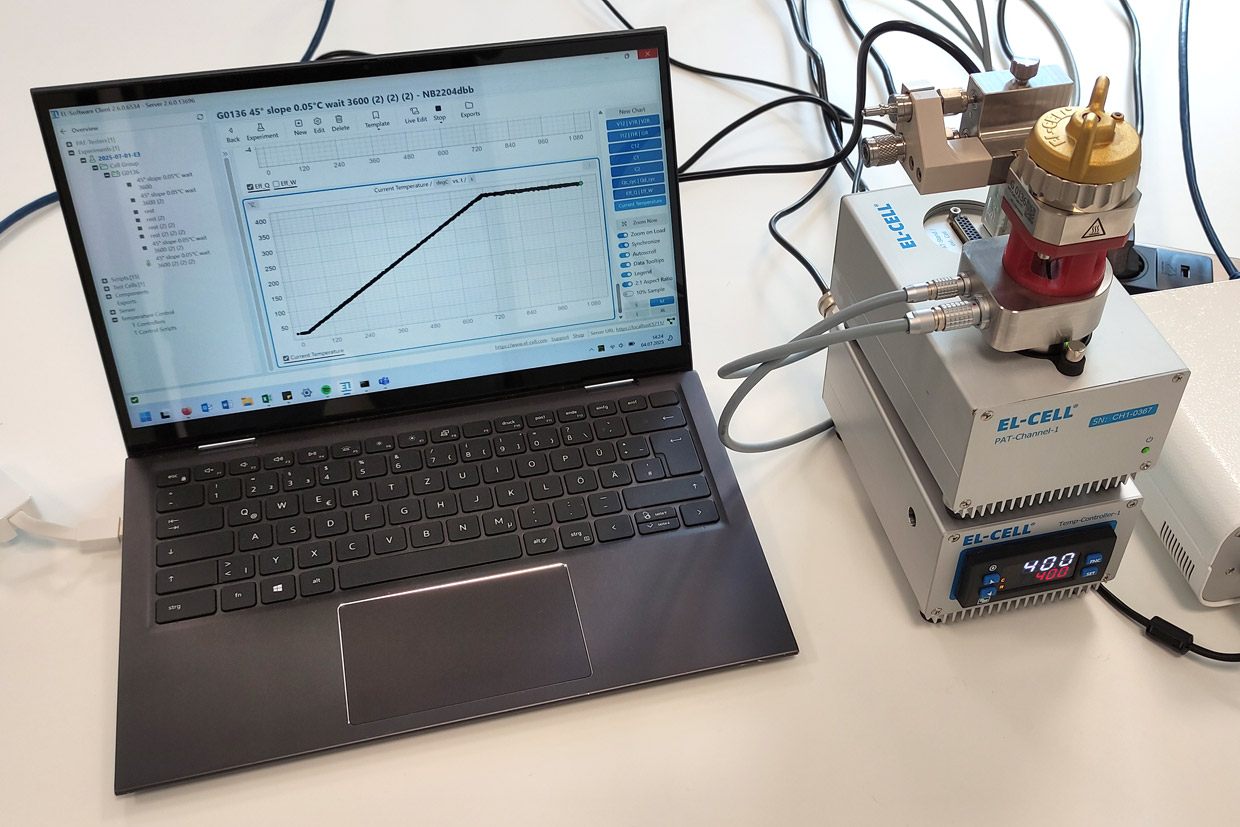

The cell base is thermally decoupled from the measurement electronics, and the heating element is positioned directly beneath the cell stack. Temperature control is managed through EL-Software, allowing for easy script-controlled temperature changes and ramps.

The reaction gases generated are channeled from the cell base to the carrier gas system and mixed via a bypass/Laval nozzle. This setup ensures that the carrier gas does not come into contact with the cell stack, thereby preventing the cells from drying out. The carrier gas system connects to the cell using Swagelok quick-connect fittings.

Additionally, there is a closable septum port for sampling and injecting reactants into the cell base.

The cell stack inside the PAT-Cell-Gas-HT is built using the PAT-HT-Core, a customized variant of the modular PAT-Core system. A reusable ceramic insulation sleeve is used here for operation at 400°C. The stainless steel plungers have also been modified to facilitate disassembly for post-mortem analysis of the cell components. These components are fully compatible with other PAT series test cells as well.

Gas Flow System

The illustration shows the addition of the reaction gases to the carrier gas system using a Laval nozzle. Separating the carrier gas flow from the cell base prevents the electrolyte from being carried away and the cell from drying out.

PAT-Cell-Gas-HT Overview

PAT-Cell design with heatable cell stack up to max. 400°C

Compatible with the PAT-Core system, uses reusable ceramic insulation sleeves for operation at high temperatures Fast and even heating, full temperature control via EL-Software with definable heating rates and ramps. Connection for carrier gas system via Swagelok quick couplings Variant with gas pressure sensor, 0 to 30 bar abs. Bypass system for injection of the reaction gases into the carrier gas. No electrolytic drag or drying out of the cell. Sealable septum port for sampling and injecting reactants into the cell interior Electronic cell tag (PAT-Button) for automatic cell identificationGallery

Recommended Docking Station and Potentiostat

PAT-Tester-x

The PAT-Tester-x offers maximum flexibility with up to 8 channels for small scale and special purpose testing.

Recommended Tools

EL-Cut

High precision cutting pliers to eliminate torn and chipped electrode edges. Recommended diameter size for use with the ECD-4-nano is 8 mm.

ECC-LiPunch

Punching tool for lithium foil. The recommended size for use with the ECD-4-nano is 9 mm.

Related Products

PAT-Tester-x-8

Fully featured potentiostat / galvanostat / impedance analyzer with up to 8 test channels.