Discover the PAT series

The science of battery testing has reached the next level.

Discover the PAT series

The science of battery testing has reached the next level with the introduction of the PAT series.

What is the PAT series?

The PAT series is a new generation of battery test cells that feature a unique single-use concept, which raises the standard of lithium-ion (Li-ion) battery research. All test cells are built around the PAT-Core, which is a highly customizable single-use compartment for the test specimen. This series enables two- and three-electrode tests of Li-ion batteries.

All PAT series test cells are designed without sockets for direct cable connections. They must, therefore, be used with docking stations such as the PAT-Stand-1, PAT-Stand-16, or the temperature-controlled PAT-Chamber-16. Because the cable connections do not need to be renewed for each testing, the parallel battery tests enable the generation of more reliable test results with less effort and in a shorter period of time.

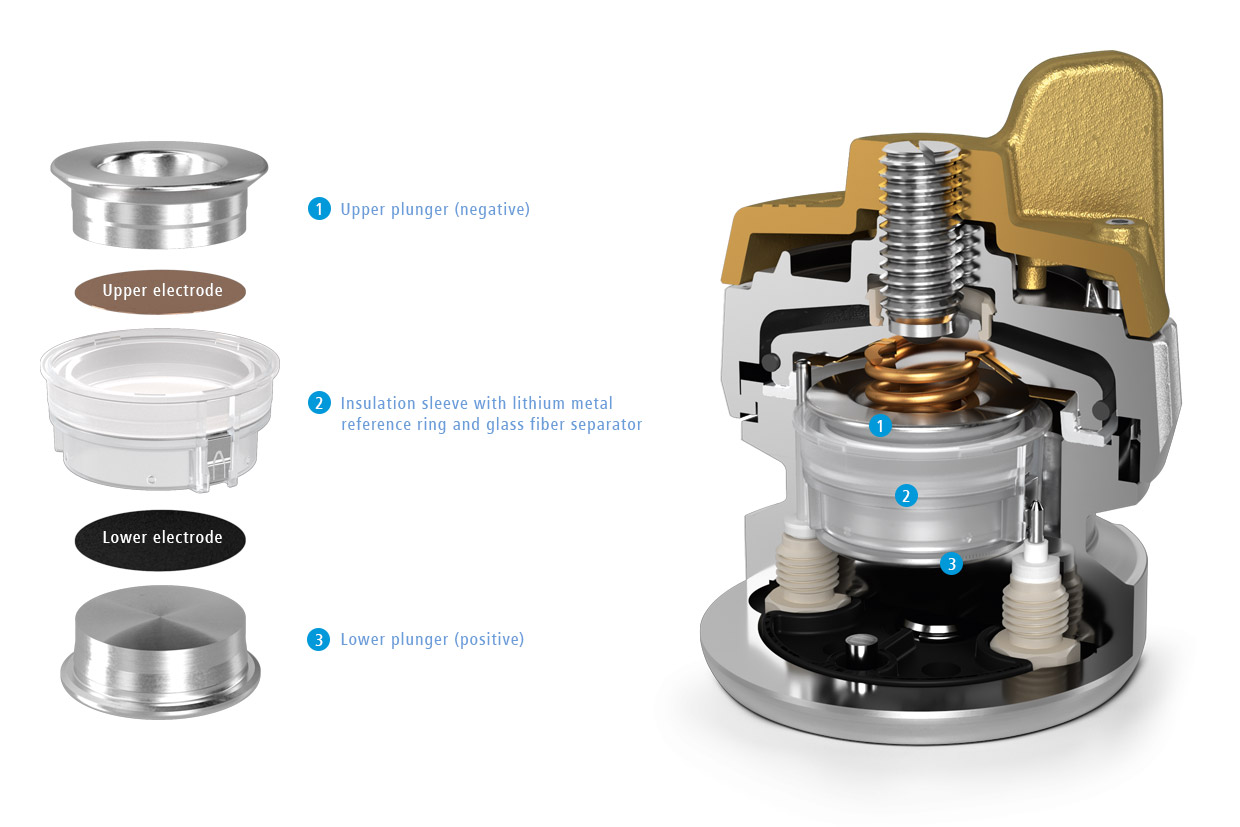

The PAT-Core

The PAT-Core is the heart of the PAT series

The PAT-Core is the essential part of the PAT-cell holding in place and precisely aligning the electrodes under test. The well-defined geometry of the PAT-Core enables high-quality two- and three electrode tests of Li-ion and other battery materials as well as supercapacitors.

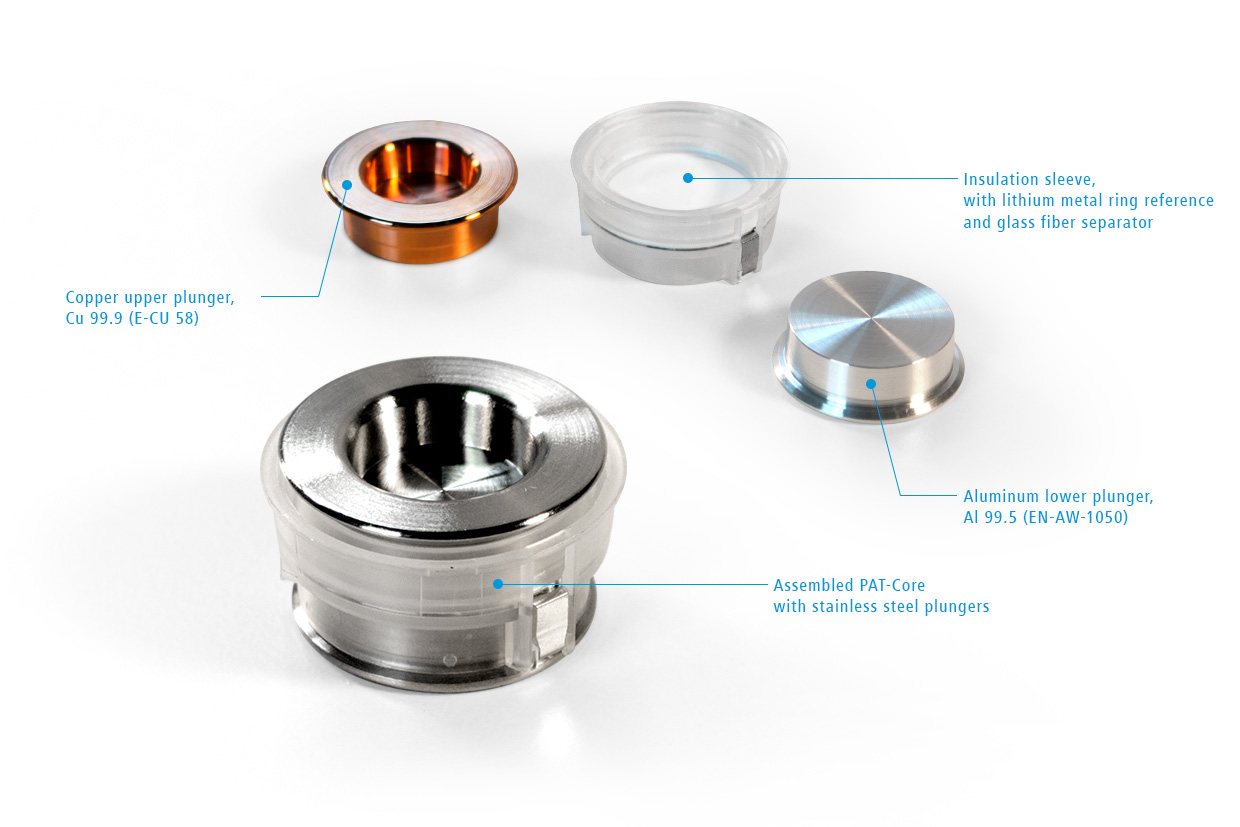

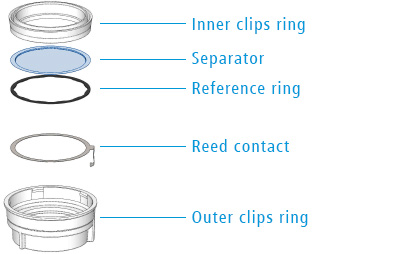

The first part of the PAT-Core is an insulation sleeve, which is made of polypropylene and is equipped with a built-in ring-shaped Li-reference electrode and a 260μm glass fiber separator. The insulation sleeve is pre-assembled under protective atmosphere at the EL-CELL® factory to ensure consistent quality for reproducible battery tests.

PAT-Core versions without a reference electrode or with a customized separator are available on request. As the current collectors, the upper and lower plungers are made of copper, aluminum, or stainless steel. This enables battery researchers to work exclusively with battery grade materials. Aluminum and copper plungers are single-use components, while the stainless steel plungers are reusable.

Different materials for your test case

The PAT-Core can be used with many different battery and capacitor types.

In general, when lithium metal is used as the negative electrode and when measuring half-cell impedances, we recommend sleeves with a built-in glass fiber separator rather than the thin technical separators such as Viledon and Celgard. Glass fiber is also the best choice when wettability is a potential issue (e.g. when using ionic liquids).

Good to know: The PAT-Core components

Upper plunger

By default, the upper plunger serves as the negative current collector. Only one plunger height is available, but it will fit any thickness of the upper electrode up to 800µm.

Following upper plungers are available:

| Upper plunger | |||

|---|---|---|---|

| Item name | Type | Order no. | |

| Upper plunger (Stainless steel) | Reusable | ECC1-01-0026-C Buy online |

| Upper plunger (Nickel) | Reusable | ECC1-01-0026-M Buy online |

| Upper plunger (PEEK) with upper feed wire (Au) and disk spring (Au) | Reusable | ECC1-01-0065-A Buy online |

| Upper plunger (Al) | Single-use | ECC1-01-0026-B Buy online |

| Upper plunger (Cu) | Single-use | ECC1-01-0026-A Buy online |

Insulation sleeves

The insulation sleeve is available with and without a ring-shaped lithium metal reference ring and with three different types of separators: a double-layered separator comprised of a 180 µm thick nonvowen PP cloth (Freudenberg FS 2226 E) and a 38 µm thick microporous UHMW-PE membrane (Lydall Solupor 5P09B), a 260µm borosilicate glass fiber separator (Whatman GF/A), and a 25µm nonwoven polyester separator pasted with Al2O3 (Freudenberg Viledon FS 3005-25).

Separator comparison:

| Separator | FS-5P (Freudenberg Viledon FS 2226E + Lydall Solupor 5P09B) | Freudenberg Viledon FS 3005-25 | Whatman GF/A |

| Thickness | 220µm | 25µm | 260µm |

| Material | PP fiber/PE membrane | PET fiber, Al2O3 | Borosilicate glass fiber |

| Porosity | FS: 67%/ 5P: 86% | 55% | 91% |

| Wettability | Good | Good | Excellent |

| Resistance to dendrites | Good | Poor | Modest |

| Ability for full cell cycle tests | Excellent | Good | Good |

| Ability for half cell cycle tests (vs. Li) | Excellent | Poor | Modest |

| Ability for full cell EIS | Excellent | Excellent | Excellent |

| Ability for half cell EIS | Modest | Poor | Good |

| Order no (sleeve with Li reference) | ECC1-00-0210-V/X | ECC1-00-0210-A/X | ECC1-00-0210-O/X |

Other separators and customized solutions are available on request. Furthermore, the sleeve is available in a disassembled state, either with or without the lithium reference ring. The standard versions are shown in the table below:

| Insulation sleeve | Article no. | Type of testing |

| with lithium ring reference, with double-layered FS-5P separator (220 µm) | ECC1-00-0210-V/x | 3 electrodes |

| with lithium ring reference, with Viledon separator (25 µm) | ECC1-00-0210-A/x | 3 electrodes |

| with lithium ring reference, with glass fiber separator (260 µm) | ECC1-00-0210-O/x | 3 electrodes |

| without ring reference, with double-layered FS-5P separator (220 µm) | ECC1-00-0210-W/x | 2 electrodes |

| without ring reference, with Viledon separator (25 µm) | ECC1-00-0210-B/x | 2 electrodes |

| without ring reference, with glass fiber separator (260 µm) | ECC1-00-0210-P/x | 2 electrodes |

Lower plunger

By default, the lower plunger serves as the positive current collector. It is available in different materials and in different “height numbers”. The proper plunger height must be chosen to ensure that the pre-assembled separator is not excessively bent during assembly of the PAT-Core. The proper plunger height number depends on both the thickness of the lower electrode and the thickness of the built-in separator.

Our configurator can help you to determine the proper lower plunger for your battery test:

PAT-Core features

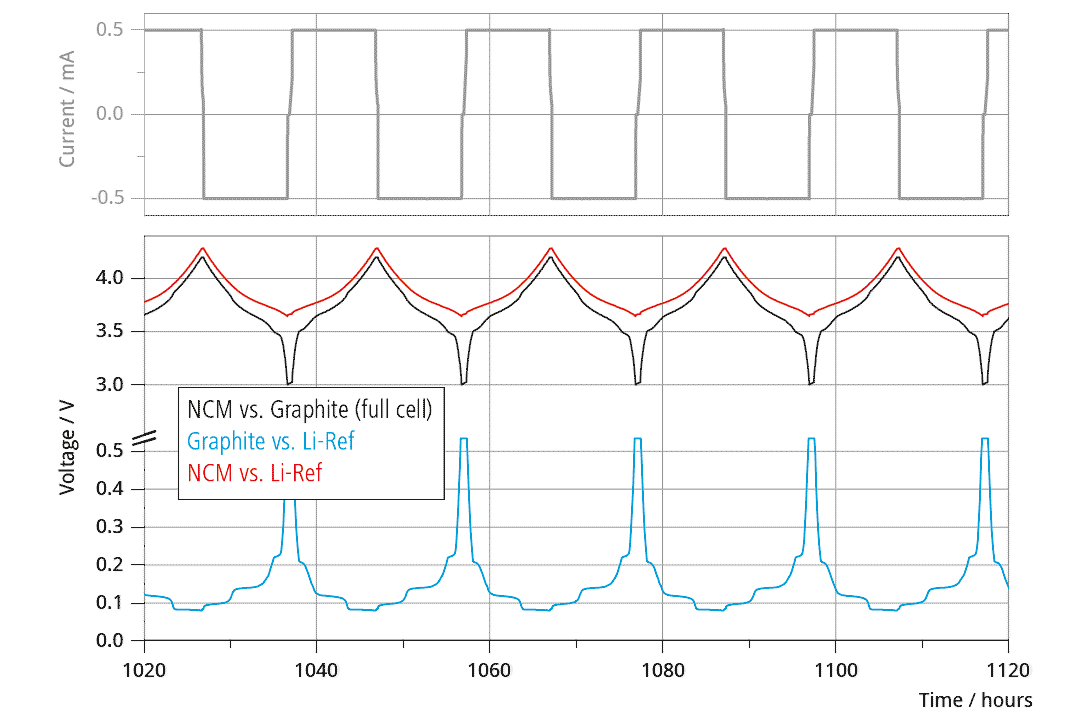

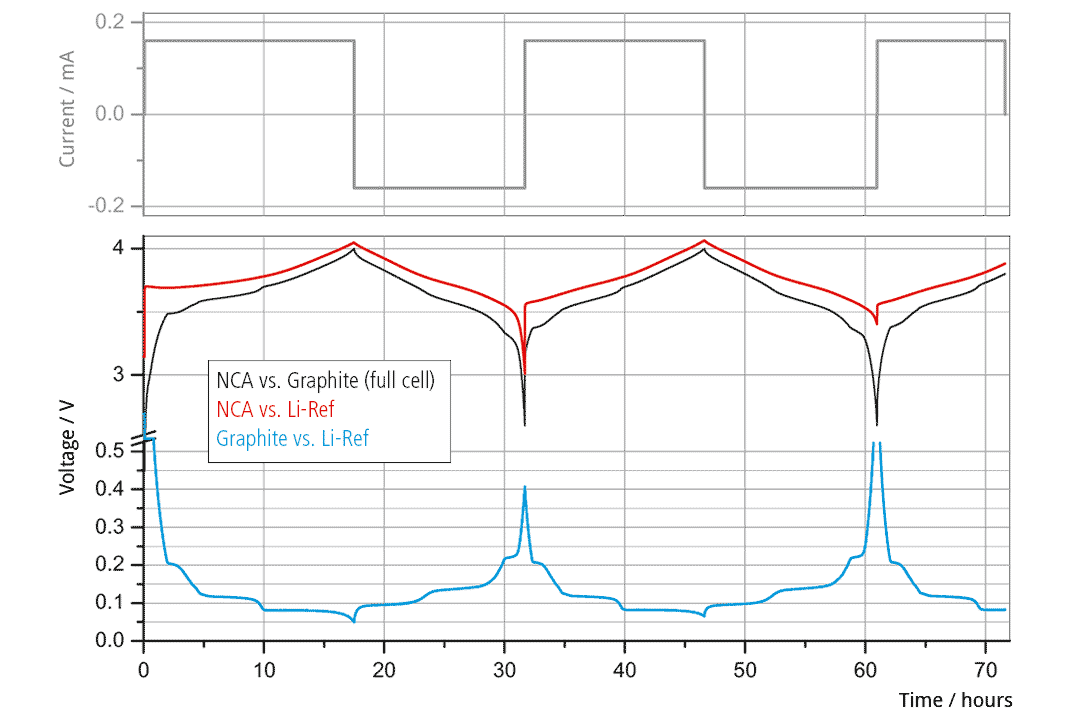

Long-term tests

The PAT-Core enables battery tests with a three-electrode setup and a duration of 1000 hours or more. This advantage is due to the new ring-shaped Li-reference electrode, which is far more time stable than point-type reference electrodes. The PAT-Core is, therefore, the perfect test system for aging studies.

Less cross contamination and corrosion

The single-use concept of the PAT series helps to reduce cross contamination between subsequent tests. Corrosion issues are also reduced. The PAT-Core consists of three single-use parts: insulation sleeve (PP), upper plunger (Cu as standard), and lower plunger (Al as standard).

All these parts are assembled, packed, and sealed under controlled atmosphere at the EL-CELL® factory. Moreover, single-use parts do not need to be cleaned and dried, which circumvents the risk of contamination with water and reduces the effort in the lab.

Please note that upper and lower plungers are also available as reusable versions in stainless steel.

Easy electrolyte filling

The PAT-Cell can be easily filled with electrolyte during the assembly procedure. The user needs only a micro-pipette to drip a defined amount of electrolyte onto the separator, which is factory preinstalled in the insulation sleeve of the PAT-Core.

The amount of electrolyte used is typically between 50 and 200μL, depending on the specific components used.

Increased productivity

The new PAT series improves productivity of battery testing. The single-use concept avoids effort that is related to cleaning and disassembling of the PAT-Cores. When used with a PAT-Stand-16, time for connecting the test cells with the potentiostat for every new battery test is saved.

Moreover, the PAT-Stand-16 saves space in the lab; its compact design holds up to 16 PAT-Cells. All these features increase the productivity of battery testing and facilitates high-throughput testing.

Products of the PAT series

Test cells

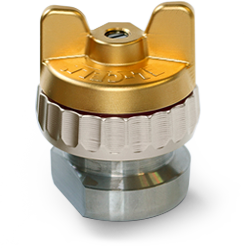

PAT-Cell

Leadless test cell for high throughput testing of Li-ion battery materials using the innovative PAT-Core concept.

- Ability to conduct long-term half cell measurements with three electrodes

- No need to clean or dry cell components due to single-use concept

- Reproducible and homogeneous mechanical pressure on electrodes

| Purpose/testing | 2-electrode, 3-electrode |

| Electrolytes | Aprotic ( e.g. LiPF6, R4NBF4) |

| Available current collectors | Cu, Al, SS |

Product details

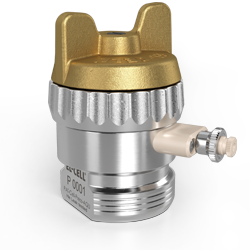

ECC-PAT-Core

Electrochemical test cell with reference electrode using the PAT-Core concept.

- Fewer mistakes from corrosion and cross contamination

- No need to clean or dry cell components

- Easy and reliable electrolyte filling during assembly

- Reliable sealing with PE seal and double cutting rings

| Purpose/testing | 2-electrode, 3-electrode |

| Electrolytes | Aprotic ( e.g. LiPF6, R4NBF4) |

| Available current collectors | Cu, Al, SS |

Product details

PAT-Cell-Aqu

Test cell for aqueous electrolytes and non-lithium battery systems.

- Superior corrosion resistance against aqueous electrolytes

- Also applicable to aprotic battery chemistries with special demands on corrosion resistance

- Specialized PAT-Core with reusable plunger made of PEEK polymer and gold current collectors

| Purpose/testing | 2-electrode, 3-electrode |

| Electrolytes | Aqueous ( e.g. H2SO4, KOH); Aprotic |

| Available current collectors | Au, Pt, Ni |

Product details

PAT-Cell-Press

Leakproof test cell for measuring gas evolution.

- PAT-Core design with or without reference electrode

- Laser welded pressure sensor, 0 to 3 bar abs

- Electrode feedthroughs with glass-to-metal seals

| Purpose/testing | 2-electrode, 3-electrode, gas analysis |

| Electrolytes | Aprotic ( e.g. LiPF6, R4NBF4) |

| Available current collectors | Cu, Al, SS |

Product details

PAT-Cell-Press-Aqu

Pressure test cell for aqueous electrolytes and non-lithium battery systems

- Superior corrosion resistance against aqueous electrolytes

- Laser welded pressure sensor, 0 to 3 bar abs

- Specialized PAT-Core with reusable plunger made of PEEK polymer and gold current collectors

| Purpose/testing | 2-electrode, 3-electrode, gas analysis |

| Electrolytes | Aqueous ( e.g. H2SO4, KOH); Aprotic |

| Available current collectors | Au, Pt, Ni |

Product details

PAT-Cell-HT

Heat resistant PAT series test cell for up to 200°C

- PAT-series test cell for 2-or 3-electrode testing at elevated temperatures

- Continuous operating temperature: up to 200°C

- Demountable HT-sleeve for self-installation

| Purpose/testing | 2-electrode, 3-electrode |

| Electrolytes | Aprotic; compatible with solid state membranes |

| Available current collectors | Cu, Al, SS |

Product details

PAT-Cell-Aqu-HT

Test cell for 2- and 3-electrode testing with aqueous and other highly corrosive electrolytes at elevated temperatures.

- Specialized PAT-Core with reusable plungers made of PEEK polymer and gold current collectors

- Compatible with solid state (ceramic) electrolyte membranes

- Reusable HT insulation sleeve for self-installation of separator or electrolyte membrane and ring-shaped reference

| Purpose/testing | 2-electrode, 3-electrode |

| Electrolytes | Aqueous ( e.g. H2SO4, KOH), Aprotic, compatible with solid state membranes |

| Available current collectors | Au, Pt, Ni |

Product details

PAT-Cell-Twin-Ref

Specialized PAT-Cell for testing simultaneously with two reference electrodes.

- Ability for conducting long-term half cell measurements with two reference electrodes

- No need to clean or dry cell components due to single-use concept

- Compatible with any potentiostat or battery tester

| Purpose/testing | 2 reference electrodes |

| Electrolytes | Aprotic (e.g. LiPF6, R4NBF4) |

| Available current collectors | Cu, Al, SS |

Product details

Docking / Test stations

PAT-Tester-i-16

The PAT-Tester-i-16 integrates a temperature controlled cell chamber and docking station with a battery tester into one single instrument.

- 16 independent channels for PAT-series test cells

- Each channel with fully featured potentiostat / galvanostat / impedance analyzer

- Integrated Peltier-temperature-control with a temperature range of +5 to +80°C

| Testing Capacity | up to 16 test cells |

| Datalogger | Simultaneous recording of both half-cell voltages and sensor signals (e.g. temperature, pressure |

| Additional features | Multi channel galvanostat / potentionstat / impedance analyzer; Temperature controlled cell chamber (Peltier) |

Product details

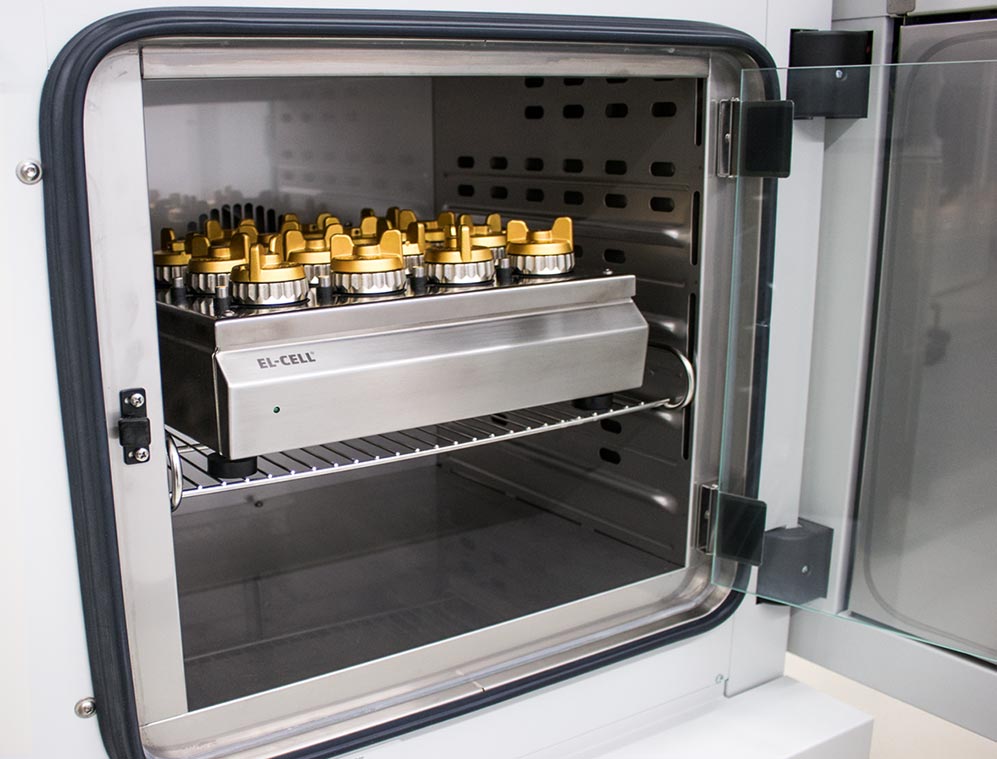

PAT-Chamber-16

Temperature-controlled docking station for PAT series test cells

- Ready for up to 16 PAT-Cells or PAT-Cell-Press for pressure monitoring

- With data acquisition of cell current, cell voltage, half-cell voltages, global temperature, individual cell pressure

- Compatible with all of today’s potentiostats and battery testers

| Testing Capacity | up to 16 test cells |

| Datalogger | Cell Current, Cell voltage, Half cell voltage, Global temperature, Individual cell pressure |

| Additional features | Temperature controlled cell chamber (Peltier) |

Product details

PAT-Stand-16

High throughput docking station for up to 16 PAT-Cells

- 4×4 docking station for up to 16 PAT-Cells

- Integrated data logger for recording half-cell voltages and temperature

- Can be placed on the bench or inside a temperature chamber

| Testing Capacity | up to 16 test cells |

| Datalogger | Cell Current, Cell voltage, Half cell voltage, Tray temperature |

Product details

PAT-Stand-4

Docking station for up to four PAT-Cells

- Compatible with all of today’s multi-channel potentiostats and battery testers

- Saves wiring effort in the lab

- Can be placed on the bench top, inside a temperature chamber or inside a glove box

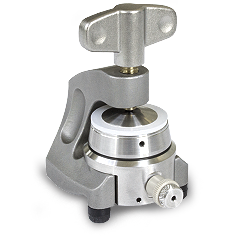

PAT-Stand-1

The ideal docking station for individual battery testing

- Can be placed on the bench-top, inside a temperature chamber, or inside a glove box

- Docking station for a single PAT-Cell or PAT-Cell-Press

- Saves wiring effort

PAT-Stand-1 U

Single-channel docking station for the most flexible operation of customized PAT-Cell designs.

- Docking station for use with a single PAT-Cell-Twin-Ref.

- May be used to connect with any other PAT series test cell. All signals of the respective test cell are available through banana sockets at the front panel.

- Compatible with any potentiostat or battery tester.

PAT-Heater-4

Heated chamber for four PAT-Cell-HT

- Heated chamber from 10°C > ambient temperature up to 200°C

- 4 x 1 docking station for up to four PAT-Cell-HT

- Flexible wiring due to easy-to-access banana sockets

| Testing Capacity | up to 4 PAT-Cell-HT |

| Datalogger | - |

| Additional features | Heated chamber from 10°C > ambient temperature up to 200°C |

Product details

PAT compatibility table

What is the right test / docking station for your PAT-Cell?

| Docking / Test station | PAT-Cell | PAT-Cell-Press | PAT-Cell-HT | PAT-Cell-Twin-Ref | PAT-Cell-Gas |

| PAT-Stand-1/PAT-Clamp-1 | C | C | C | C | |

| PAT-Stand-1 U | C | ||||

| PAT-Clamp-1 + PAT-Press Box + T-Chamber | C | C T P | C | C T | |

| PAT-Stand-1 + PAT-Press Box + T-Chamber | C | C T P | C | C T P | |

| PAT-Stand-4 | C | C | C | C | |

| PAT-Stand-16 | C | C | C | C | |

| PAT-Chamber-16 | C | C T P | C | C T P | |

| PAT-Heater-4 | C T | ||||

| PAT-Tester-x | C | C T P | C | C T P | |

| PAT-Tester-i-16 | C | C T P | C | C T P | |

| Supported features: | Colors: | ||||

| C: charge/discharge/impedance | all test cell features supported | ||||

| T: temperature control | some test cell features not fully supported | ||||

| P: gas pressure | test cell incompatible |

Videos

You can download all of our videos directly from our video page.