PAT-Cell-Gas

Battery Test Cell for Gas Analysis in a Flow-Through Setup

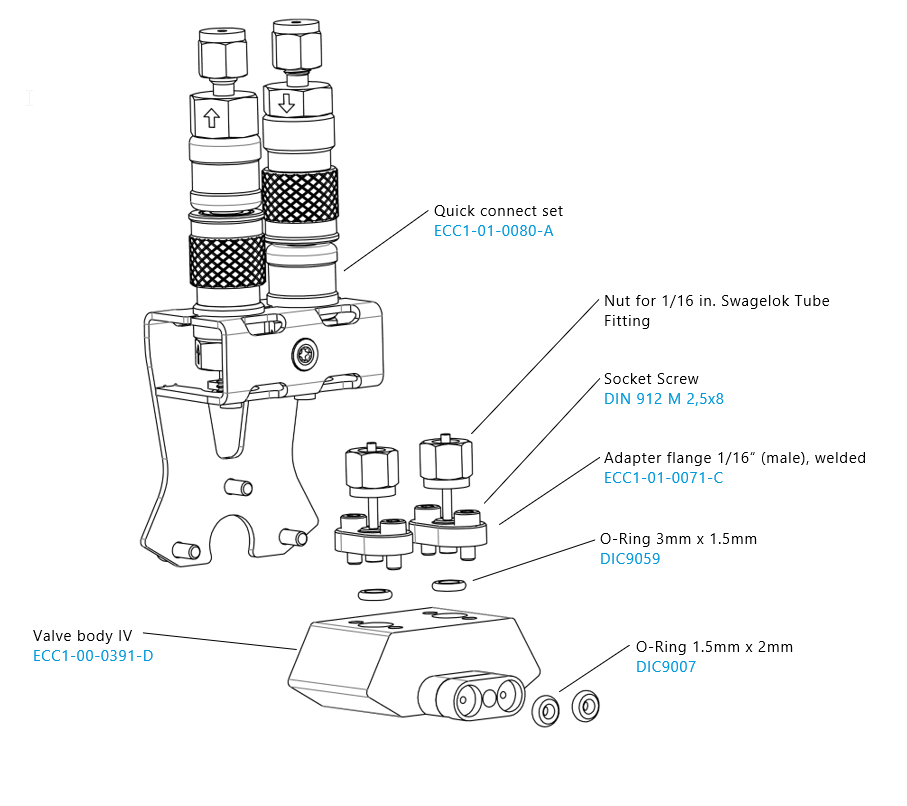

Gas In- and Outlet

-20 °C

+80 °C

PAT-Cell-Gas

Battery Test Cell for Gas Analysis in a Flow-Through Setup

᛫ Gas Sample Port

Optional Features:

᛫ Pressure Sensor

0

3 bar

᛫ Temperature Sensor

Typical Use Cases

- In-situ gas analysis in a flow-through setup

- Time-resolved gas analysis

- Quantifying gas evolution /consumption

Key Features

Cableless test cell with all advantages of the PAT-Core

Gas inlet and outlet with 1/16 inch Swagelok Tube Fitting

Optional digital gas pressure sensor, pressure range of 0 to 3 bar abs.

Optional digital temperature sensor, temperature range -20° C to 80° C

Optional gas sample port

Product Description

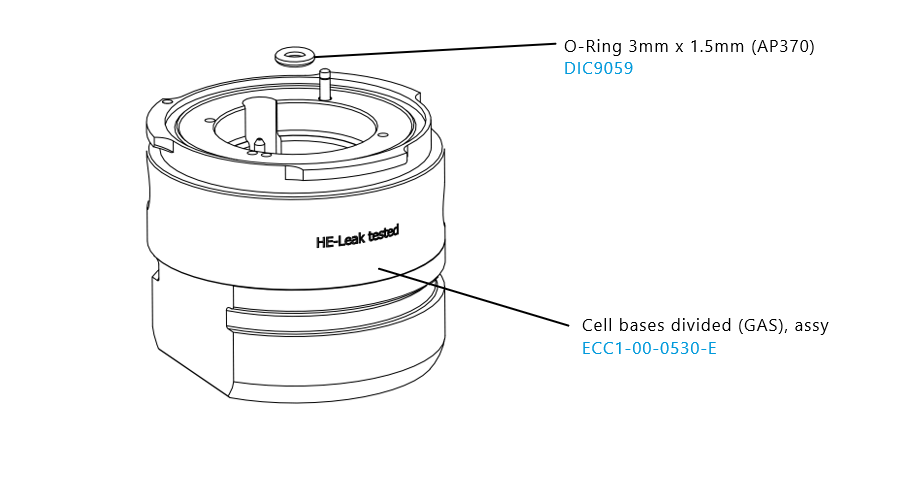

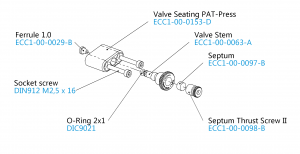

The PAT-Cell-Gas is a test cell dedicated for in-situ gas analysis of battery materials in a flowthrough set-up. For this purpose, the test cell features a gas inlet and outlet with self-locking couplings that are compatible with 1/16″ Swagelok tube fittings. In addition, options that include built-in pressure and temperature sensors or a septum port for gas sampling with a syringe are available.

The cell stack is placed on top of a perforated or grooved current collector (flow field), which is to be purged with a gentle stream of gas. The lower electrode must be gas permeable, so as to allow for gas exchange with the feed gas. Typically, the cell is used with gas diffusion electrodes (such as for Li-air) or with Li-ion battery electrodes with a meshed current collector. The special design minimizes backmixing of the gas from the flowfield back into the headspace, and is thus very suitable for time-resolved gas analysis with a mass spectrometer, for example.

The PAT-Cell-Gas variants with pressure sensor are designed for use with EL-CELL potentiostats to take full advantage of all sensor functions.

Product Variants

Working Modes

Mode 1: Air mode

The lower plunger, equipped with a perforated plate, enables the electrochemical characterization of gas diffusion electrodes used, for instance, in Li-air batteries. The lower electrode is contacted by and “breathes” through the perforated stainless steel current collector supporting it. During operation, the pressure gradient building up between the cell headroom and the gas volume below the perforated plate effectively prevents back-mixing. The relatively large volume below the perforated is at the expense of time resolution, but makes this solution robust against clogging of the gas path.

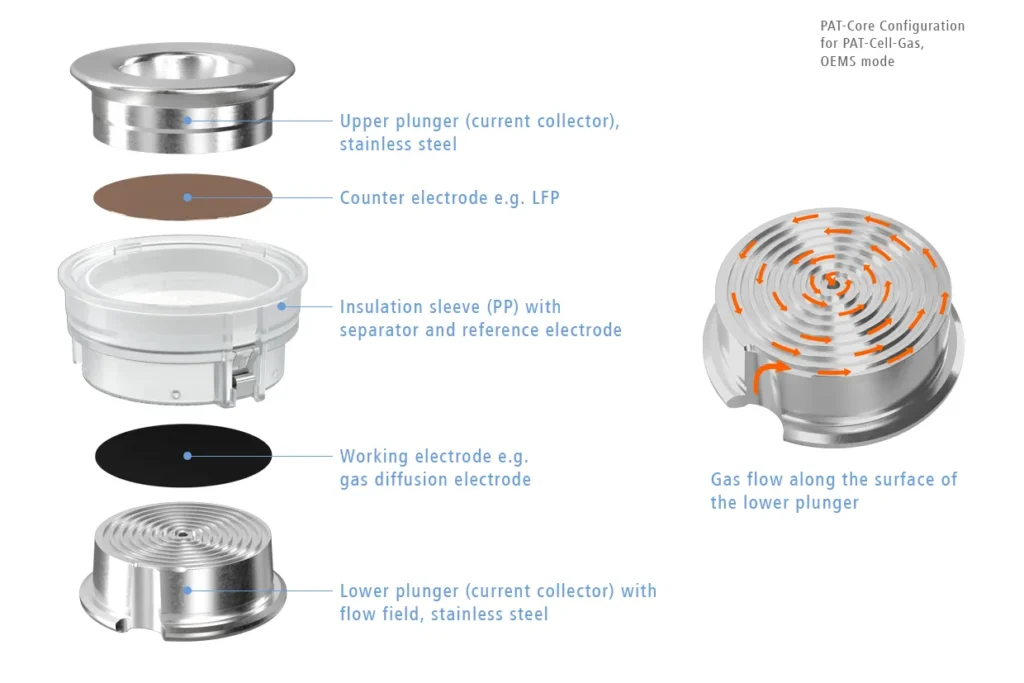

Mode 2: OEMS mode

The PAT-Core setup, utilizing a lower plunger with a flow field, provides nearly perfect plug-flow of the purge gas, which is essential for quantitative, time-resolved analysis. Gases evolved or consumed at the working electrode can be analyzed through the composition change of the gas stream that is passed along the spiral-type flow field below the working electrode. The composition of the outgoing gas can be analyzed, for example, by mass spectrometry. The pressure gradient between the cell headroom and the spiral-type flow field effectively prevents back mixing. This, combined with the tiny gas volume of the flow field, ensures the best possible time resolution.

Specifications

Specifications

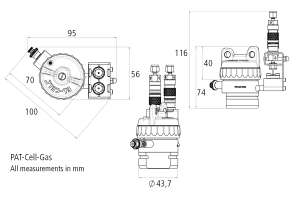

| Length | 100 mm |

| Width | 70 mm |

| Height | 116 mm |

| Weight | 0.6 kg |

| Gas connection | 1/16 inch Swagelok Tube Fitting |

| Electrode diameter | 18 mm |

| Temperature resistance | -20 to 80° C |

| Gas pressure sensor: | |

| Range | 0 to 3 bar abs. |

| Accuracy | < 5 mbar |

| Resolution | < 0.2 mbar |

| Temperature Sensor | |

| Range | -20 °C to +80 °C |

Compatible Potentiostats/Battery Tester

| Charge/Discharge/Impedance | Read Pressure Sensor | Read Temperature Sensor | Temperature Control | |

| PAT-Tester-x-8* | * | |||

| PAT-Tester-i-16 | ||||

| Third-party Potentiostat | ||||

| *with external temperature chamber |

Compatible PAT Docking Stations

| Charge/Discharge/Impedance | Read Pressure Sensor | Read Temperature Sensor | |

| PAT-Clamp-1 | |||

| PAT-Stand-1 | |||

| PAT-Stand-1 U | |||

| PAT-Stand-4 | |||

| PAT-Stand-16 | |||

| PAT-Chamber-16 | |||

| PAT-Heater-4 |

Documentation

Frequently Asked Questions

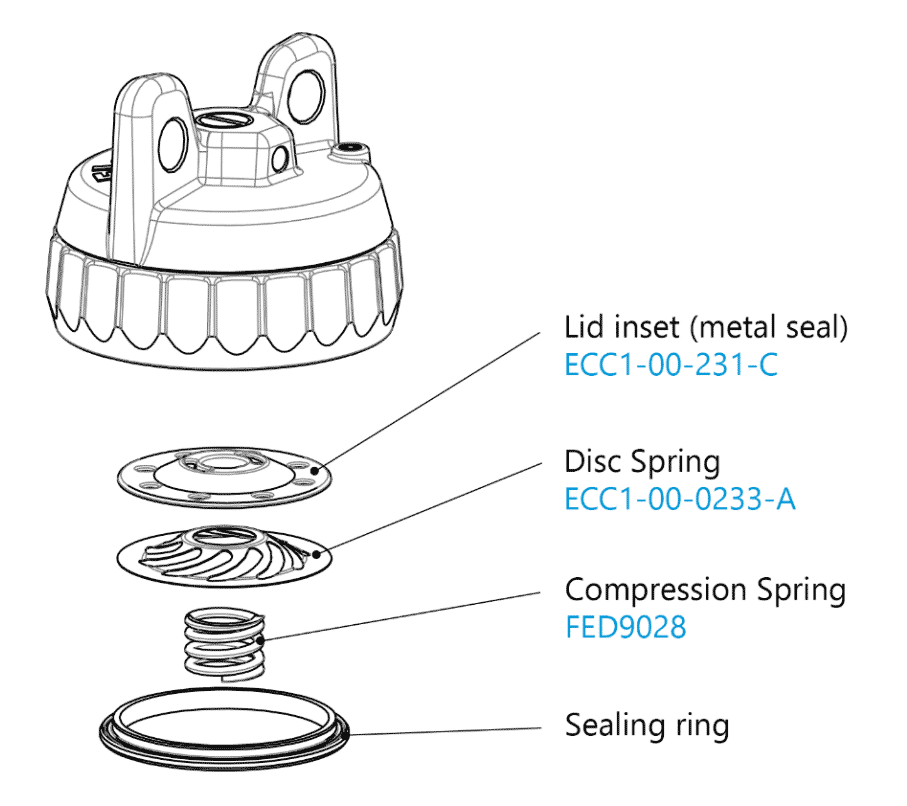

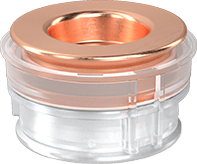

Many test cells in the PAT series are already supplied with a metal seal lid (Item name: Screw cap insulated (PAT)) as standard. If you still have an older cell, you can use the following features to determine whether the existing cover is suitable for metal seals.

The compatible cell lid for use with metal seals has two holes on the top and a white or black inset made of PPS in the lid, which serves as insulation.

As the two holes can also be found on older cell lids without insulation, you should always check whether the inset is present. Non-compatible cell lids have no inset at all.

The PAT-Cell-Gas II transmits its signal data via the digital I²C bus and therefore does not require any additional devices. Please note that an EL-Cell potentiostat is required to read out the pressure and temperature sensor signals.

Battery Test Cell for Measuring Gas Evolution / Consumption

The PAT-Cell-Gas is a test cell dedicated for in-situ gas analysis of battery materials in a flowthrough set-up. For this purpose, the test cell features a gas inlet and outlet with self-locking couplings that are compatible with 1/16″ Swagelok tube fittings. In addition, options that include built-in pressure and temperature sensors or a septum port for gas sampling with a syringe are available.

The cell stack is placed on top of a perforated or grooved current collector (flow field), which is to be purged with a gentle stream of gas. The lower electrode must be gas permeable, so as to allow for gas exchange with the feed gas. Typically, the cell is used with gas diffusion electrodes (such as for Li-air) or with Li-ion battery electrodes with a meshed current collector. The special design minimizes backmixing of the gas from the flowfield back into the headspace, and is thus very suitable for time-resolved gas analysis with a mass spectrometer, for example.

The PAT-Cell-Gas variants with pressure sensor are designed for use with EL-CELL potentiostats to take full advantage of all sensor functions.

PAT-Cell-Gas Overview

- In-situ gas analysis in a flow-through setup

- Time-resolved gas analysis

- Quantifying gas evolution /consumption

Cableless test cell with all advantages of the PAT-Core

Gas inlet and outlet with 1/16 inch Swagelok Tube Fitting Optional digital gas pressure sensor, pressure range of 0 to 3 bar abs. Optional digital temperature sensor, temperature range -20° C to 80° C Optional gas sample port

PAT-Cell-Gas II SP

- Gas sample port

- Gas Pressure sensor, 0 to 3 bar abs (digital)

- Temperature sensor -20°C to +80°C (digital)

- Gas inlet and outlet

- Optimized lid for use with metal seal

PAT-Cell-Gas II P

- Gas Pressure sensor, 0 to 3 bar abs (digital)

- Temperature sensor -20°C to +80°C (digital)

- Gas inlet and outlet

- Optimized lid for use with metal seal

PAT-Cell-Gas S

- Gas sample port

- Gas inlet and outlet

- Optimized lid for use with metal seal

PAT-Cell-Gas

- Gas inlet and outlet

- Optimized lid for use with metal seal

| Length | 100 mm |

| Width | 70 mm |

| Height | 116 mm |

| Weight | 0.6 kg |

| Gas connection | 1/16 inch Swagelok Tube Fitting |

| Electrode diameter | 18 mm |

| Temperature resistance | -20 to 80° C |

| Gas pressure sensor: | |

| Range | 0 to 3 bar abs. |

| Accuracy | < 5 mbar |

| Resolution | < 0.2 mbar |

| Temperature Sensor | |

| Range | -20 °C to +80 °C |

Compatible Potentiostats / Battery Testers

| Charge/Discharge/Impedance | Read Pressure Sensor | Read Temperature Sensor | Temperature Control | |

| PAT-Tester-x-8* | * | |||

| PAT-Tester-i-16 | ||||

| Third-party Potentiostat | ||||

| *with external temperature chamber |

Compatible PAT docking stations

| Charge/Discharge/Impedance | Read Pressure Sensor | Read Temperature Sensor | |

| PAT-Clamp-1 | |||

| PAT-Stand-1 | |||

| PAT-Stand-1 U | |||

| PAT-Stand-4 | |||

| PAT-Stand-16 | |||

| PAT-Chamber-16 | |||

| PAT-Heater-4 |

How can I identify whether my PAT-Cell is suitable for use with metal seals?

The compatible cell lid for metal seals (Item name: Screw cap insulated (PAT)) can be recognized by two features. It has two holes on the top and a white or black inset made of PPS in the lid, which serves as insulation.

As the two holes can also be found on older cell lids without insulation, you should always check whether the inset is present. Non-compatible cell lids have no inset at all.

Do you always need a PAT-Press-Box to operate the PAT-Cell-Press?

The PAT-Press-Box is required to read and record the analog pressure signal of a PAT series test cell.

It is required in the following docking stations:

The following devices provide the necessary functions themselves, therefore no PAT-Press-Box is required:

*x = Height number (50 to 800). Use our configurator to determine the proper lower plunger.

Recommended PAT-Core configurations

This information can be used as a guide for building the PAT-Cell-Gas. More PAT-Core setups can be found here.

3-electrode testing with aprotic LiPF6 based electrolytes

2-electrode testing with aprotic LiPF6 based electrolytes

3-electrode testing with aprotic supercap electrolytes

*x = Height number (50 to 800). Use our configurator to determine the proper lower plunger.

**AC = Activated carbon

Recommended potentiostats

The PAT-Cell-Press test cell is fully supported by the following potentiostats:

PAT-Tester-i-16

The PAT-Tester-i-16 integrates a temperature controlled cell chamber and docking station with a battery tester into one single instrument.

PAT-Tester-x-8

The PAT-Tester-x-8 offers maximum flexibility with up to 8 channels for small scale and special purpose testing.

Recommended tools

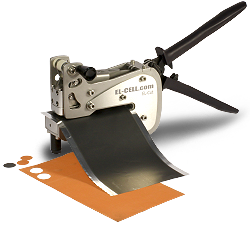

EL-Cut

High precision cutting pliers to eliminate torn and chipped electrode edges. Recommended diameter size for use with the PAT-Cell-Gas is 18 mm.

ECC-LiPunch

Punching tool for lithium foil. The recommended size for use with the PAT-Cell-Gas is 18 mm.

Related products

PAT-Cell-Gas-HT

Battery test cell for heating the cell stack up to 400°C and analyzing the gases produced

PAT-Tester-x-8

Modular multi-channel potentiostat for special and small-scale testing

Product details